-

Our Opening Hours Mon- Fri

-

+91 9324123488 / 8591611252

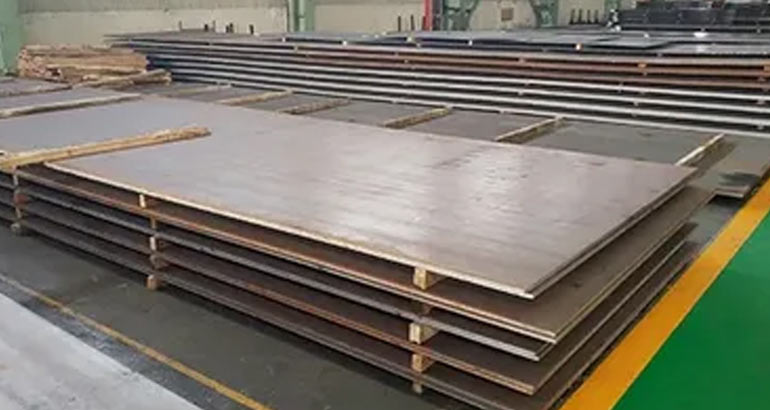

ASME SA 387 GR 12 Alloy Plates

Built for utilization in hoisted temperature administration, ASME Sa387 Grade 12 is a chrome molybdenum carbon alloy steel for utilization in weldable pressure vessels and modern boilers.

The material advantages from included chromium which gives incredible consumption and oxidation safety making it perfect for harsh administration applications in the oil and gas industry.

Vandan Steel & Engg. co. stocks Sa387 Grade 12 Class 2 and can dispatch to any goal, around the world. All our plates accompany plant confirmation and stampings.

ASME SA 387 Grade 12 Alloy Plate, ASME SA 387 Grade 12 Alloy Plate Manufacturers, ASME SA 387 Grade 12 Alloy Plate Manufacturers in India, ASME SA 387 Grade 12 Alloy Plate Suppliers,ASME SA 387 Grade 12 Alloy Plate Stockists, ASME SA 387 Grade 12 Alloy Plate Exporters,ASME SA 387 Grade 12 Alloy Plate Traders,ASME SA 387 Grade 12 Alloy Plate Dealers, ASME SA 387 Grade 12 Alloy Plate Importers, Authorized Distributors Of ASME SA 387 Grade 12 Alloy Plate, Authorized Exporters Of ASME SA 387 Grade 12 Alloy Plate,authorised Traders Of ASME SA 387 Grade 12 Alloy Plate, Authorised Importers Of ASME SA 387 Grade 12 Alloy Plate,autorised Suppliers Of ASME SA 387 Grade 12 Alloy Plate. SA387 Gr.12 Cl 2 Steel Plates, Sa 387 Gr 12 Cl.2 Plates, ASME SA387 Alloy Steel Gr 12 Class 2 Plates, SA387 Chromium-molybdenum Steel Gr 12 Class 2 Steel Plates, SA387 Gr.12 Cl 2 Alloy Steel Plates Distributor, ASME SA387 Alloy Steel Grade 12 Class Plate

ASME SA 387 Grade 12 Alloy Plate Suppliers In Mumbai,ASME SA 387 Grade 12 Alloy Plate Stockists In Mumbai, ASME SA 387 Grade 12 Alloy Plate Exporters In Mumbai,ASME SA 387 Grade 12 Alloy Plate Traders In Mumbai ,ASME SA 387 Grade 12 Alloy Plate Dealers In Mumbai, ASME SA 387 Grade 12 Alloy Plate Importers In Mumbai, Authorised Distributors Of ASME SA 387 Grade 12 Alloy Plate In Mumbai, Authorised Exporters Of ASME SA 387 Grade 12 Alloy Plate In Mumbai,authorised Traders Of ASME SA 387 Grade 12 Alloy Plate In Mumbai, Authorised Importers Of ASME SA 387 Grade 12 Alloy Plate In Mumbai,autorised Suppliers Of ASME SA 387 Grade 12 Alloy Plate In Mumbai. SA387 Grade 12 Cl 2 Alloy Steel Plates Stockist In Mumbai, India. ASME SA 387 Grade 12 Cl 2 Low Alloy Steel Plate, ASME SA 387 Grade 12 Crmo Cl 2 Boiler Quality Plates Exporter, A387 Grade 12 Class 2 Hr Plates

EQUIVALENTS

| BS | EN | ASTM/ASME | DIN |

|---|---|---|---|

| 620 B | 13 CRMO 45 | SA387-12-2 | 13 CRMO 44 |

SPECIFICATION CHROMIUM & MOLYBDENUM CONTENT ASME SPECIFICATION

| Designation | Nominal Chromium Content (%) |

Nominal Molybdenum Content (%) |

|---|---|---|

| SA387 Grade 12 | 1.00% | 0.50% |

CHEMICAL REQUIREMENTS

| Element | Chemical Composition (%) | |

|---|---|---|

| SA 387 Grade 12 | ||

| Carbon: | Heat Analysis: | 0.05 - 0.17 |

| Product Analysis: | 0.04 - 0.17 | |

| Manganese: | Heat Analysis: | 0.40 - 0.65 |

| Product Analysis: | 0.35 - 0.73 | |

| Phosphorus: | Heat Analysis: | 0.035 |

| Product Analysis: | 0.035 | |

| Sulphur (max): | Heat Analysis: | 0.035 |

| Product Analysis: | 0.035 | |

| Silicon: | Heat Analysis: | 0.15 - 0.40 |

| Product Analysis: | 0.13 - 0.45 | |

| Chromium: | Heat Analysis: | 0.80 - 1.15 |

| Product Analysis: | 0.74 - 1.21 | |

| Molybdenum: | Heat Analysis: | 0.45 - 0.60 |

| Product Analysis: | 0.40 - 0.65 |

TENSILE REQUIREMENTS FOR CLASS 2 PLATES

| Designation: | Requirement: | Grade 12 |

|---|---|---|

| SA387 Grade 12 | Tensile strength, ksi [MPA] | 65 to 85 [450 to 585] |

| Yield strength, min, ksi [MPa]/(0.2% offset) | 40 [275] | |

| Elongation in 8 in. [200mm], min % | 19 | |

| Elongation in 2 in. [50mm], min, % | 22 | |

| Reduction of area, min % | ,. |

Tension Test Requirements: The material shall be tested using a test specimen and will confirm to the tensile requirements as outlined in above table.

Other requirements: The following requirements and testing procedures (which are not mandatory) are considered suitable for Chrome Molybdenum steel:

Vacuum treatment

Product Analysis

Additional Tension Test

Charpy V-Notch Impact Test

Drop Weight Test

High Temperature Tension Test

Ultrasonic Examination

Magnetic Particle Examination